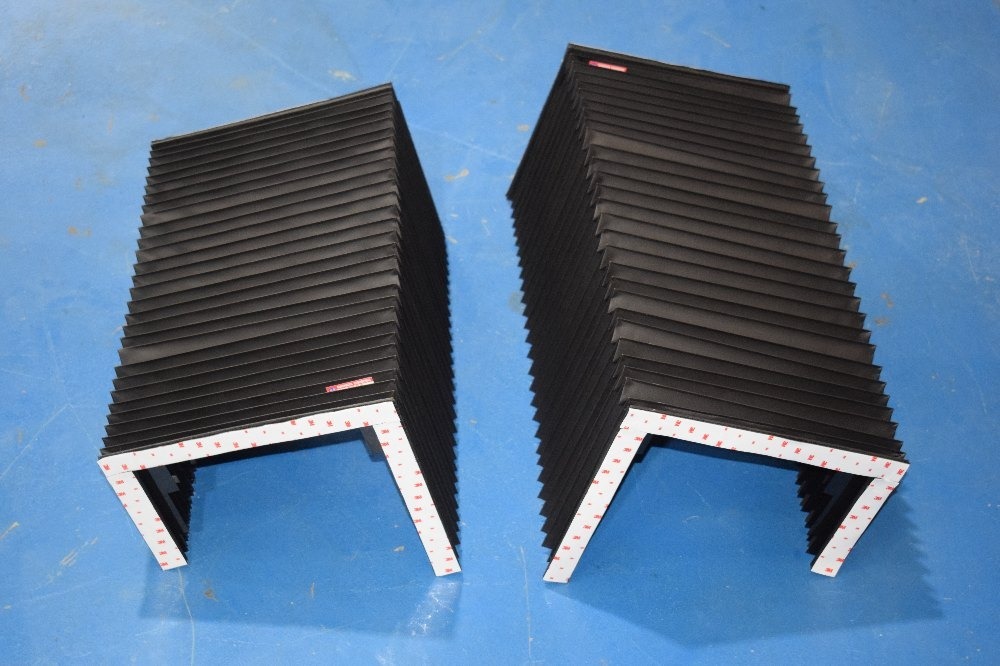

Circular Bellow

Made from a core of rigid polyamide fabric with layers of PVC on either side.

These systems are applied to protect spindles, shafts and columns and the optical fiber in laser machines.

Parts of the circular bellows

Fuelles circulares

Nylon fabric with layers of PVC.

Stitching.

Silicon coating.

PVC slides.

Steel hoop for large bellows.

Air outlet holes.

Support for fastening bellows to machine.

Collar for fastening to the machine.

Opening systems

Fuelles circulares

For very heavy vertical protective elements, tecnifuelle has a number of opening systems:

SYSTEM 1

Stretching device using staples located on the support frame, on as many folds as required, depending on the size of the bellows.

SYSTEM 2

Scissors-type stretching device, ideal for elements that are not guided by the intermediary frames.

Ways of securing ends to the machine

In the system with steel frames, the anchoring type and anchoring holes must be specified by the customer.

In systems where Velcro is used to fasten the bellows, one side is joined to the end frame of the bellows and, the other to the frame of the machine.

END FRAMES FOR

FASTENING BELLOWS

TO THE MACHINE COMPLETE FOLD HALF FOLD FRAME LARGER THAN

FOLD FASTENED WITH

VELCRO

Fuelles circulares Fuelles circulares Fuelles circulares Fuelles circulares Fuelles circulares

Fabrics

Fuelles circulares

FT: Heat-welded bellows

FC: Stitched bellows

Temperature ºC

Ref.

material Type of fabric and coating Thickness

(mm) Temporary Continuous Operating conditions FT FC

Min Max

TPP-23 POLIESTER + PVC 0, 23 110 -25 70 DUST GUARD,

ACID MEDIUMS USABLE USABLE

TPP-35 POLIESTER + PVC 0, 35 110 -25 70 DUST GUARD,

ACID MEDIUMS USABLE USABLE

TPP-60 POLIESTER + PVC 0, 6 110 -25 70 DUST GUARD,

ACID MEDIUMS USABLE

TPP-100 POLIESTER + PVC 1 110 -25 70 DUST GUARD,

ACID MEDIUMS USABLE

TPPU-23 POLIESTER + POLYURETHANE 0, 23 220 -25 150 RESISTANT TO OILS IN

EMULSION AND GREASE USABLE USABLE

TPPU-35 POLIESTER + POLYURETHANE 0, 35 220 -25 150 RESISTANT TO OILS IN

EMULSION AND GREASE USABLE USABLE

TPPU-60 POLIESTER + POLYURETHANE 0, 60 220 -25 150 RESISTANT TO OILS IN

EMULSION AND GREASE USABLE

TPHY-50 POLIESTER + HYPALON 0, 50 250 -15 140 RESISTANT TO MINERAL

OIL, GREASE USABLE

TPHY-100 POLIESTER + HYPALON 1 250 -15 140 RESISTANT TO MINERAL

OIL, GREASE USABLE

TNPU-35 NOMEX + POLYURETHANE 0, 35 400 -30 200 HOT SWARF,

LASER BEAMS, OILS USABLE USABLE

TARPU-35 ARAMIDE + POLYURETHANE 0, 35 400 -20 200 HOT SWARF,

OILS, GREASE USABLE USABLE

TFVS-35 FIBREGLASS +

SILICONING + PVC 0, 35 400 -40 250 FOR HIGH TEMPERATURES CYLINDERS, CEILINGS... USABLE USABLE

TFCAL-35 CARBON FIBRE + ALUMINIUM 0, 35 500 -40 280 FOR HIGH TEMPERATURES USABLE

TFVV-35 FIBREGLASS + VITON + POLYURETHANE 0, 35 600 -40 280 FOR HIGH TEMPERATURES USABLE USABLE